Projected Capacitive Touch Screen Solutions Manufacturer in Taiwan - AMT

AMT has made significant investments in the research and development of Projected Capacitive touch screens. We focus our efforts on continuously advancing the functionality of PCAP products. The perfect combination of AMT PCAP touchscreens, controllers, and drivers allow us to offer best-in-class total PCAP touch solutions. With their outstanding performance, AMT PCAP touch products meet the needs of all fields, including industrial, medical, and business applications.In this section, you can find detailed information regarding the features of AMT PCAP touchscreens and touch controllers. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

Projected Capacitive Touch Screen Solutions

Industrial, Medical, Transportation, Outdoor, Kiosk, HMI Projected Capacitive Touch Screen, Touch Panel and Touch Controller

AMT has made significant investments in the research and development of Projected Capacitive touch screens. We focus our efforts on continuously advancing the functionality of PCAP products. The perfect combination of AMT PCAP touchscreens, controllers, and drivers allow us to offer best-in-class total PCAP touch solutions. With their outstanding performance, AMT PCAP touch products meet the needs of all fields, including industrial, medical, and business applications.

In this section, you can find detailed information regarding the features of AMT PCAP touchscreens and touch controllers.

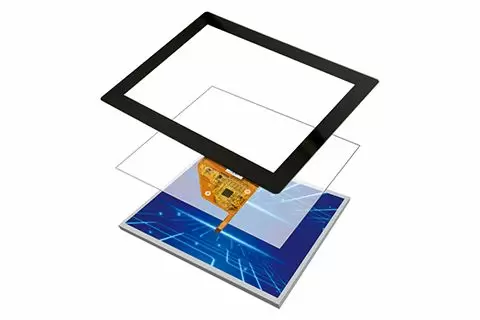

One For All Projected Capacitive Touch Solution

AMT stands out as the sole provider capable of supporting three controllers concurrently with...

DetailsProjected Capacitive Touch Screen

AMT projected capacitive (PCAP) touch screens are specifically designed and manufactured for industrial,...

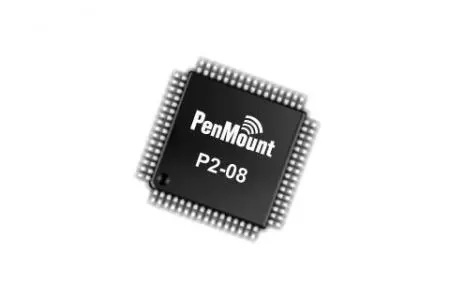

DetailsProjected Capacitive Touch Screen Controllers

PenMount projected capacitive (PCAP) touch screen controllers are a vital part of providing...

DetailsAqua Proof Projected Capacitive Touch

AMT has developed a Projected Capacitive (PCAP) touch button product that has excellent water-resistant...

DetailsAnti-UV Projected Capacitive Touch Screen

An Ultraviolet Light (UV) Resistant projected capacitive (PCAP) touch screen resists damage...

DetailsProjected Capacitive Controller IC

PenMount projected capacitive controller ICs can be provided individually and surface mounted...

DetailsProjected Capacitive Touch Screen Solutions Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Projected Capacitive Touch Screen Solutions. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.