Support

In this section, you can find standard drawings of AMT resistive and PCAP touchscreens, as well as PenMount touch controllers for common operating systems. In the "PenMount Touchscreen Controller Datasheets" area you can download datasheets for PenMount touch controllers with detailed specifications. Instructions on how to install resistive or PCAP touch controller drivers and use the utility software can be found in the "PenMount Touchscreen Controller User Guides" area.

AMT Standard Products Overview

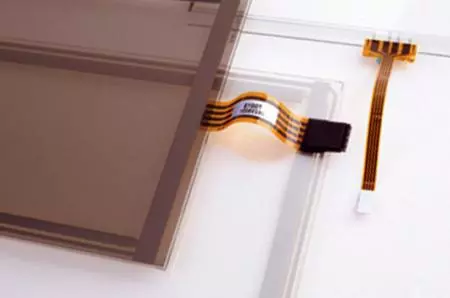

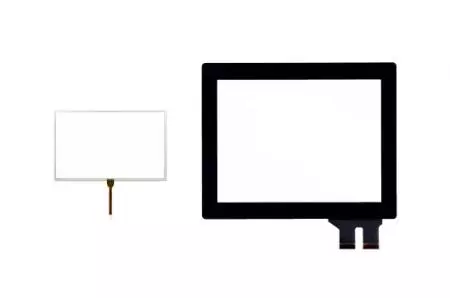

AMT touch products encompass a wide range of items and services from touch panel hardware to controller software customization services. As the world's...

Read moreAMT Standard Drawings

AMT touch products encompass a wide range of items and services from touch panel hardware to controller software customization services. As the world's...

Read morePenMount Touchscreen Controller Datasheets

PenMount touch screen controllers can fully support AMT touch screen products. PenMount is specialized touch panel controller solution supplier that represents...

Read morePenMount Touchscreen Controller User Guides

PenMount touch screen controllers can fully support AMT touch screen products. PenMount is specialized touch panel controller solution supplier that represents...

Read moreCleaning Touchscreens

Maintaining touchscreens is simple. AMT recommend using a dry, clean cloth to wipe off dust regularly. Use alcohol for cleaning only when necessary. When...

Read more