Projected Capacitive Touch Screen Manufacturer in Taiwan - AMT

AMT projected capacitive (PCAP) touch screens are specifically designed and manufactured for industrial, medical, outdoor, and transportation applications. Standard AMT projected capacitive touch screens feature wide temperature tolerance, UV resistance, noise immunity, glove operation support, and more. They support various glass cover thicknesses, provide customizable value-added options, and are compatible with different touch controllers. AMT touch screens are widely deployed across industrial computers, medical devices, outdoor systems, Vehicle, marine, aerospace, EV chargers, kiosks, and more. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

Projected Capacitive Touch Screen

Industrial-Grade Projected Capacitive Touch Screen Solutions

AMT projected capacitive (PCAP) touch screens are specifically designed and manufactured for industrial, medical, outdoor, and transportation applications. Standard AMT projected capacitive touch screens feature wide temperature tolerance, UV resistance, noise immunity, glove operation support, and more. They support various glass cover thicknesses, provide customizable value-added options, and are compatible with different touch controllers. AMT touch screens are widely deployed across industrial computers, medical devices, outdoor systems, Vehicle, marine, aerospace, EV chargers, kiosks, and more.

What Makes AMT Projected Capacitive Touch Screens Different?

The key difference between AMT’s projected capacitive touch screens and other products on the market lies in our industrial-grade design and specifications. From structural design to user experience, every detail showcases exceptional expertise and technical prowess. AMT’s standard projected capacitive touch screen series features numerous advanced capabilities, exceeding industry benchmarks and meeting the stringent demands of high-end products, ensuring smooth market launches.

Wide Temperature Design

- Operating Temperature: -40°C to +85°C; Storage Temperature: -50°C to +90°C

- Industrial-grade specifications suitable for extreme temperature variations

UV Resistance Design

- Meets QUV ASTM G154 Cycle 1 & Q-Sun MIL-STD-810H Pro1 – 1,000 hours

- Equivalent to approximately 4.5 years under Miami outdoor exposure without significant yellowing

High Controller Compatibility

- A single touch screen can support PenMount, ILITEK, or EETI touch controllers simultaneously

- Design allows easy controller switching based on project requirements

Superior Quality

- Thorough testing and inspection before shipment

- Well-managed production process with full traceability

Projected Capacitive Touch Screen Features

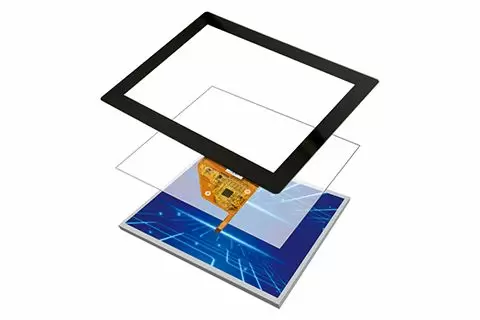

AMT offers not only touch screens but also complete projected capacitive touch solutions. From size selection and structural design to controller pairing and firmware/software integration, every detail is thoughtfully engineered to enhance the user experience.

- Complete solution including touch screen, controller, firmware, and software

- Standard sizes from 3.5” to 32”

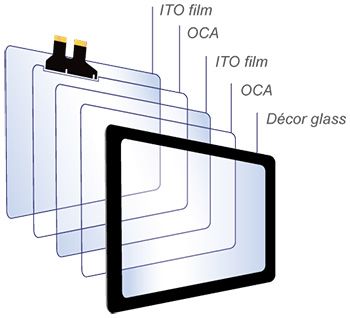

- GFF (Glass-Film-Film) structure for flexible cover glass designs

- AFF (Adhesive-Film-Film) structure for local glass lamination

- Controller available in board or COF (Chip on Flex) form

- Supports multi-touch functionalit

- Customizable cover glass shapes and printing options

Projected Capacitive Touch Solution Functions

Stability and reliability are basic requirements for touch panels in different applications. AMT’s projected capacitive solutions combine multiple advanced functions to ensure outstanding performance even under extreme conditions.

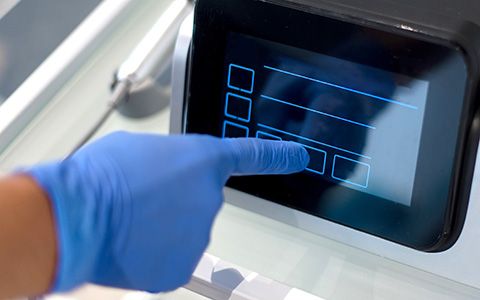

Glove Operation

- Compatible with rubber, cotton, work, and medical gloves

- Customizable for thicker gloves or special coated gloves

Noise Immunity

- IEC 61000-4-2 : Electrostatic Discharge Level 4, class B

- IEC 61000-4-3 : Radiated Susceptibility Level III 10 V/m, criteria A

- IEC 61000-4-6 : Conducted Susceptibility Level III 15 Vrms, criteria A

- IEC EN60601-1-2 RS (Radiated Sus0ceptibility) 9 ~ 28V/m, Class A

Impact Resistance

- Supports cover glass thickness up to 10 mm

- Enhanced signal strength allows stable operation even on thick glass

Waterproof Handling

- Small amounts of water: unaffected touch operation in dry areas

- Large amounts of water: touch function automatically disables

- Water removed: touch functionality automatically resumes

- Option to integrate Aqua Switch into cover glass borders

Value-Added Services for Projected Capacitive Touch Screens

AMT fully understands that every customer’s needs are unique. We offer a wide range of value-added features, such as anti-infrared protection, waterproof key functionality, and anti-corrosion options, to help you create a customized touch screen solution that perfectly fits your application environment. AMT provides highly customized projected capacitive touch screen solutions, along with multiple optional value-added features, including:

- Anti-Infrared: Blocks outdoor infrared rays to prevent excessive internal system temperature, helping to reduce internal temperatures by approximately 6°C.

- EMI Shielding: Protects against electromagnetic interference, passing IEC61000 and DO-160 certification standards.

- Anti-Corrosive: Special anti-corrosion design prevents functional failure caused by corrosive gases in outdoor or industrial environments.

- Aqua Switch: Projected capacitive waterproof key technology prevents false touches caused by water spray.

- Heater: Assists in warming up the device or defogging.

- Glass Surface Treatments: Offers various surface options, including clear, anti-glare (AG), anti-reflective (AR), antiviral and antibacterial coating (Vi-K), and Anti-ESD coating.

- All-Black:Color difference ΔE ≤1, between LCD display area and touch screen black frame.

Applications for Projected Capacitive Touch Screens

AMT PCAP touch products are deployed across a wide range of industries, from industrial automation to medical diagnostics, outdoor signage, and smart transportation.

- Industrial

- Medical

- Outdoor

- Vehicle

- Rail Transportation

- Marine

- Mission Critical

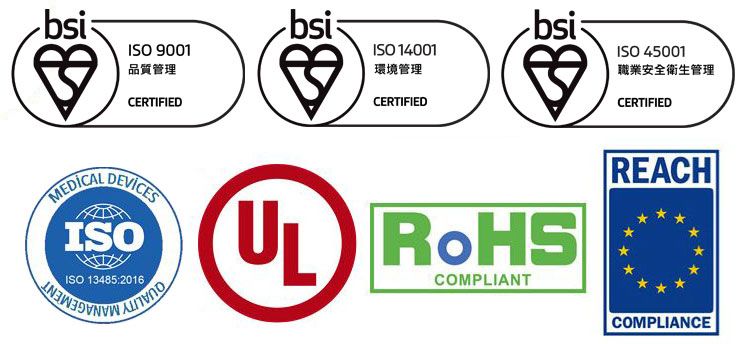

Compliance with International Standards

AMT meets international standards and holds globally recognized certifications, giving customers confidence in our products. Certified under ISO, UL, REACH, RoHS standards, AMT ensures its products meet quality, safety, and environmental regulations.

We have earned ISO 9001:2015 certification for quality management and ISO 13485:2016 certification for medical device quality systems, ensuring our projected capacitive touch screen solutions meet regulatory requirements across Europe, the United States, Canada, and beyond.

- Video

- Related Products

Projected Capacitive Touch Screen Controllers

PenMount projected capacitive (PCAP) touch screen controllers are a vital part of providing...

Details

Projected Capacitive Touch Screen Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Projected Capacitive Touch Screen. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.