Standard Resistive Touch Screen Manufacturer in Taiwan - AMT

AMT resistive touch screens operate on a very simple principle that is reliable and consistent. Applications that prioritize command confirmation and overall safety often use resistive touch screens. AMT supplies resistive touch screens in sizes from 3.0" to 24" and hardware, software, resistive touch screen controllers, and drivers for operating systems from DOS to Windows 10 as well as Linux, Android, and QNX. Resistive touch screens can be constructed with 4-, 5-, or 8-wire circuitry. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

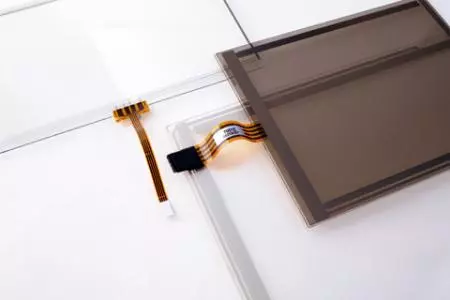

Standard Resistive Touch Screen

4-wire, 5-wire, 8-wire resistive touch screen

AMT resistive touch screens operate on a very simple principle that is reliable and consistent. Applications that prioritize command confirmation and overall safety often use resistive touch screens. AMT supplies resistive touch screens in sizes from 3.0" to 24" and hardware, software, resistive touch screen controllers, and drivers for operating systems from DOS to Windows 10 as well as Linux, Android, and QNX. Resistive touch screens can be constructed with 4-, 5-, or 8-wire circuitry.

Resistive Touch Panel Design

4-wire Resistive Touch Screen

4-Wire Resistive Touch Screen

4-wire resistive touch screens are suitable for small or medium sized products such as PDAs and hand-held devices. These panels utilize X+, X-, Y+ and Y- lead outs at the four edges of the screen. When contact is made, X/Y read-outs are then read by the controller and converted into the correct coordinates.

5-wire Resistive Touch Screen

5-Wire Resistive Touch Screen

In a 5-wire resistive touch screen, the top conductive layer is only responsible for voltage detection while voltage is applied alternately on the X and Y axes of the bottom conductive layer.

8-wire Resistive Touch Screen

8-Wire Resistive Touch Screen

8-wire resistive touch screens operate in the same fashion as 4-wire resistive touch screens, except an extra sensing wire is added to compensate for voltage falloff at the edges of the bus bar due to resistance (disrupting uniformity) as the size of the touchscreen increases. An 8-wire structure offers 4 additional screen read-outs, circuit protection, and is well suited for screens from 6" to 22".

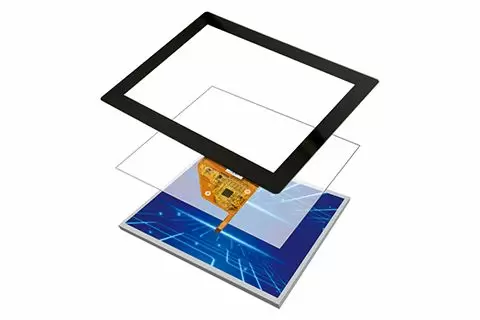

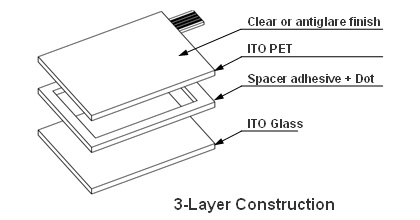

Resistive Touch Panel Construction

Resistive Touch Screen-3-Layer Construction

3-Layer Resistive Touch Screen Construction

3-Layer resistive touch screens feature film-on-glass construction with a single circuit layer bonded to a scratch-resistant surface layer, over a layer of spacer adhesive, over a bottom layer of glass integrating a conductive coating.

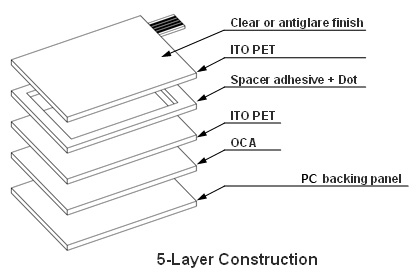

Resistive Touch Screen-5-Layer Construction

5-Layer Resistive Touch Screen Construction

AMT's 5-layer resistive touch screen construction features two layers of ITO film bonded to acrylic or polycarbonate providing two layers of circuitry with an interposing spacer adhesive with the bottom ITO layer optically bonded to the backing panel.

AMT only manufactures 5-layer panels as OEM special orders based on individual customer needs and environmental requirements.

Resistive Touch Screen Surface Finish

AMT offers anti-glare and clear surface finishes for resistive touch screen. An antiglare finish is desirable in environments where glare from ambient lighting may interfere with LCD screen visibility and/or the likelihood of frequent scratching is high. AMT antiglare finish offers the highest antiglare index and provides the strongest resistance to environmental reflection. If ambient glare is not a concern, AMT’s clear finish provides the best possible image quality and superior visual results.

Resistive Touch Screen Tail

AMT provides a wide range of tail termination types for all configurations. AMT supplies 3 types of tail, allowing customers to choose the most suitable component for their needs.

Resistive Touch Screen Tail - Integral

- Integral

- Same material as the top film.

- Sturdy construction.

Resistive Touch Screen Tail - HSC

- HSC

- Maximum flexibility.

- Narrower bend radius available.

- Compatible with Matrix resistive touch screens.

Resistive Touch Screen Tail - FPC

- FPC

- A Flexible Printed Circuit (FPC) refers to flexible electronics or flex circuits. It is produced by laminating copper strips between two PI/PET layers.

- Withstands more repeated connections.

- Narrowest available bend radius.

- Compatible with standard resistive and LR resistive touch screens.

Connectors

AMT touch screens can be equipped with the following connector types, depending on application requirements:

- ZIF

- AMP (plain or with latch)

- AMPC (AMP compatible) with latch

- Berg (FCI)

- Resistive Touch Screen Connectors ZIF

- Resistive Touch Screen Connectors AMP

- Resistive Touch Screen Connectors AMPC with Latch

- Resistive Touch Screen Connectors BERG

Specifications

| Optical | ● Surface Finish: Antiglare or Clear ● Light Transmission: > 80% ● Haze: 1.5 ~ 20% (depends on design) |

|---|---|

| Mechanical | ● Sizes: 3" to 24" diagonal size ● Construction: Film-on-glass, Film-Film-PC or others ● ITO Glass Thickness: 0.7mm, 1.1mm, 1.8mm, 2.8mm ● Tail Design: FPC type, Integral tail or others ● Tail Terminator: ZIF, Berg, AMP, AMP compatible or others ● Input Method: Finger, Gloved Finger, Stylus ● Activation Force: 0.1N to 1.0N depending on design ● Surface Hardness: 3H or higher |

| Environmental | ● Operating Temperature: -20°C to 70°C ● Storage Temperature: -40°C to 80°C ● Operating Humidity: ◎ If temp. ≧ 40°C, humidity less than 80% RH ◎ If Temp. < 40°C, humidity less than 90% RH ◎ No Dew Condensation ● Storage Humidity: Ambient Humidity |

| Electrical | ● Insulation Resistance: 10M ohm@25V DC ● Linearity: ◎ < 1.5% for 4-, 8-wire touch ◎ < 1.0% for 5-wire touch inner area ◎ < 1.5% for 5-wire touch perimeter area ● Contact Bounce: < 15ms ● Operating Voltage: 5.5 V ● Contact Current: 70mA (maximum) |

- Related Products

Resistive Touch Screen Control Board USB Interface

PenMount offers PM6300A control board with USB interface . The PM6300A supports 4, 8, and 5 wire...

DetailsResistive Touch Screen Control Board RS-232 Interface

PenMount resistive touch screen control boards communicate with the system via a RS-232 interface...

DetailsResistive Touch Screen Control Board RS-232 & USB Interface

The PenMount combination interface resistive touch screen control board has two types which...

Details

Standard Resistive Touch Screen Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Standard Resistive Touch Screen. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.