Optical Bonding Advantages Manufacturer in Taiwan - AMT

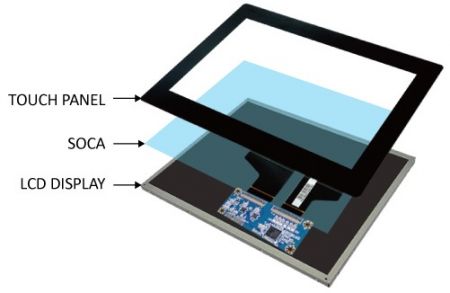

There are air bonding and optical bonding methods for bonding the touch screen and the display. Air bonding is to use mouth-shaped double-sided tape for bonding. Optical bonding is to use OCA covering the entire display area for bonding. Many companies request adopting optical bonding for their products these days. Optical bonding technology utilizes either liquid optically clear adhesive (OCR) or solid optically clear adhesive (OCA) to affix the touch screen to the LCD so that there is no air gap between the two layers. This approach can effectively reduce parallax while improving the durability and optical performance of the touch screen. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

Optical Bonding Advantages

Improve LCD optical performance

There are air bonding and optical bonding methods for bonding the touch screen and the display. Air bonding is to use mouth-shaped double-sided tape for bonding. Optical bonding is to use OCA covering the entire display area for bonding. Many companies request adopting optical bonding for their products these days. Optical bonding technology utilizes either liquid optically clear adhesive (OCR) or solid optically clear adhesive (OCA) to affix the touch screen to the LCD so that there is no air gap between the two layers. This approach can effectively reduce parallax while improving the durability and optical performance of the touch screen.

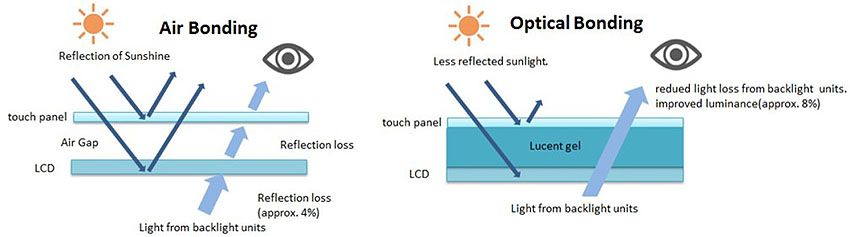

The main difference between the two bonding methods is whether there is an air layer between the touch screen and the display. When there is an air layer between the touch screen and the display, the reflectivity of light will increase and the transmittance will decrease due to the difference in refractive index, and the image of the display will not look clear and vivid.

Optical bonding can completely laminate the touch panel and the LCD panel so that there is no air gap between the touch panel and the LCD. This can reduce parallax, decrease the reflection of external light sources, and improve the penetration rate of the backlight. These all contribute to an even better optical solution for LCD monitors.

Features

- Reduce reflectance rate

- Increase LCD light transmittance rate

- Minimize visual disparity

- Shock absorption

- No dew condensation

- High reliability

- Video

Optical Bonding Advantages Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Optical Bonding Advantages. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.