Optical Bonding Manufacturer in Taiwan - AMT

AMT provides in-house optical bonding service. Our optical bonding uses our own Lucent Gel solid optically clear adhesive (SOCA). The base material is silicone, which has excellent weather resistance, yellowing resistance, UV resistance, and impact resistance. It can improve the reliability of LCD displays, and meet a wide range of application requirements such as industrial, medical, outdoor, marine, vehicle...etc. AMT optical bonding is produced in high-quality, in-house, can be quickly bonded, shortens time to market and lead times, reduces shipping costs, and provides customers one stop service with comprehensive technical support. AMT can also source LCD models to bond to an AMT touch screen, further reducing the hassle of sourcing individual components from multiple vendors.In this section, you can find detailed information regarding the features of AMT optical bonding. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

Optical Bonding

Manufacturer of Optical Bonding

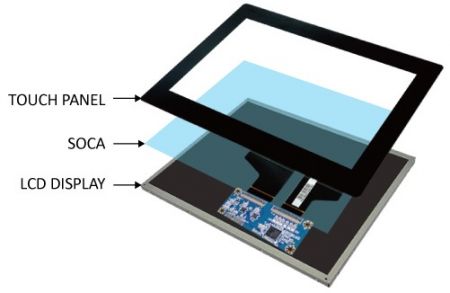

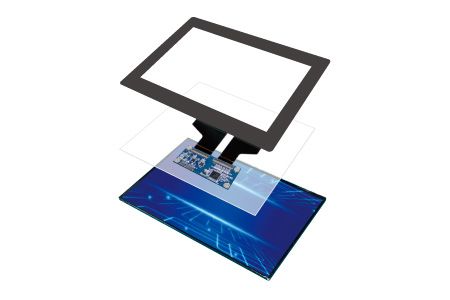

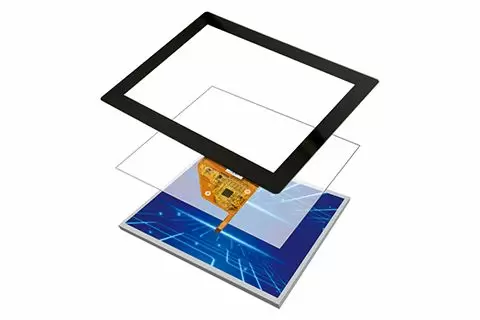

AMT provides in-house optical bonding service. Our optical bonding uses our own Lucent Gel solid optically clear adhesive (SOCA). The base material is silicone, which has excellent weather resistance, yellowing resistance, UV resistance, and impact resistance. It can improve the reliability of LCD displays, and meet a wide range of application requirements such as industrial, medical, outdoor, marine, vehicle...etc. AMT optical bonding is produced in high-quality, in-house, can be quickly bonded, shortens time to market and lead times, reduces shipping costs, and provides customers one stop service with comprehensive technical support. AMT can also source LCD models to bond to an AMT touch screen, further reducing the hassle of sourcing individual components from multiple vendors.

In this section, you can find detailed information regarding the features of AMT optical bonding.

Optical Bonding Advantages

There are air bonding and optical bonding methods for bonding the touch screen and the display....

DetailsOptical Bonding Technology

In industrial, medical, automotive, and outdoor applications, the quality and reliability of optical...

DetailsLucent Gel SOCA

Lucent gel is a proprietary silicone based solid optically clear adhesive (SOCA). Lucent gel has a number...

DetailsOptical Bonding Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Optical Bonding. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.