Anti-UV Coating Manufacturer in Taiwan - AMT

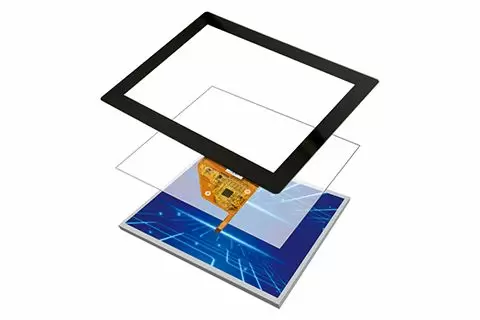

AMT's self-developed Anti-UV ink can be coated on the back of the glass, effectively blocking UV penetration. Prolonged exposure to sunlight can cause plastics to yellow, haze, bubble, or crack to varying degrees due to UV damage. AMT's Anti-UV ink can perfectly complement the printing ink on the cover glass frame. The printing ink can be directly stacked on top of it, protecting both the view area of the screen and the printing ink itself from UV damage. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

Anti-UV Coating

UV Resistant Coating

AMT's self-developed Anti-UV ink can be coated on the back of the glass, effectively blocking UV penetration. Prolonged exposure to sunlight can cause plastics to yellow, haze, bubble, or crack to varying degrees due to UV damage. AMT's Anti-UV ink can perfectly complement the printing ink on the cover glass frame. The printing ink can be directly stacked on top of it, protecting both the view area of the screen and the printing ink itself from UV damage.

UV radiation is classified into three types: UVA (wavelength 400-315nm), UVB (wavelength 315-280nm), and UVC (wavelength 280-100nm). While the Earth's ozone layer blocks the majority of the sun's UV radiation, 98.7% of the UV radiation that reaches the Earth's surface is UVA. This type of radiation is particularly detrimental to plastics, accelerating the degradation of the plastics, leading to yellowing, loss of transparency, and brittleness or cracking of structural materials.

We subject glass printed with anti-UV ink to Q-SUN and QUV ultraviolet aging tests, simulating outdoor UV exposure. The Q-SUN test replicates a full-spectrum environment, while the QUV test directly exposes the glass to UVA radiation. AMT's Anti-UV ink successfully pass the Q-SUN MIL-STD-810H Pro 1 - 500 hours and QUV ASTM G154 Cycle 1 - 500 hours testing standards, demonstrating their exceptional reliability and durability in extreme environments.

Features

- Applying Anti-UV ink on the back of glass

- UV transmittance:≤5%@365nm (thickness of dry film ≥ 10um)

- ASTM G154 Cycle 1 - 500 hours

- MIL-STD 810H PRO 1 -500hours

Specification

- Transmittance(GFF):≥ 90%

- Surface Hardness:≥ H

- Viscosity: 3000~15000 cps

- Solid content: >30%

Applications

- Outdoor kiosks

- Interactive digital billboards

- Gasoline stations

- EV charging stations

Anti-UV Coating Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Anti-UV Coating. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.