True-Flat Resistive Touch Screen Manufacturer in Taiwan - AMT

AMT true flat touch panel product lines consist of two categories-Touch Window and Framed Touch, putting touch panel, side frames and chassis together into a true flat styling, in combination of versatile outlooks as well as gorgeous colors, to create a sense of neat and high-end design. In the past, when using no-front bezel design to match up with true flat touch products for different style purposes as fashion and elegance in either consumer or commercial markets, the attentions of the consumers are successfully drawn; recently, for some of the industrial and medical applications, they also start to make introduction of true flat touch panel, to produce the products with elegant and neat styles. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

True-Flat Resistive Touch Screen

Multi color bezel true-flat resistive touch panel

AMT true flat touch panel product lines consist of two categories-Touch Window and Framed Touch, putting touch panel, side frames and chassis together into a true flat styling, in combination of versatile outlooks as well as gorgeous colors, to create a sense of neat and high-end design. In the past, when using no-front bezel design to match up with true flat touch products for different style purposes as fashion and elegance in either consumer or commercial markets, the attentions of the consumers are successfully drawn; recently, for some of the industrial and medical applications, they also start to make introduction of true flat touch panel, to produce the products with elegant and neat styles.

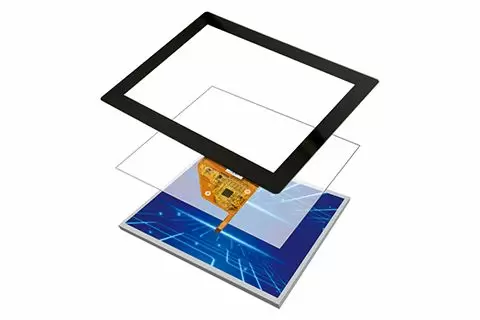

Touch Window True-Flat Resistive Touch Screen

The top layer of AMT Touch Window is a graphic overlay with printed graphic to optical laminated onto the resistive touch panel, and this will enable the keys to be designed directly on the printed part in the surroundings of touch panel; for the edge of touch panel and its four corners, any shape can be cut and ground according to the designs of the customers, as to the wiring of tail, one can choose to drill a hole on the ITO glass or with a notch on the edge. AMT possesses with unique technologies, and even with treatment procedures, such as cutting, edge grinding or hole drilling, the Touch Window will still be kept with its good linearity.

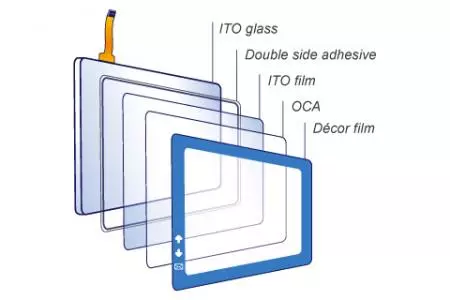

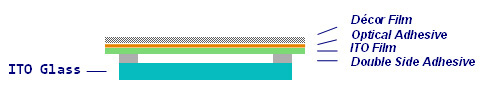

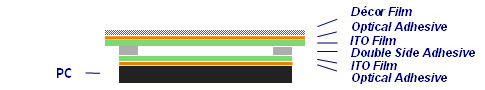

Construction

- Film-Film-Glass Construction (Generally the width and length of the upper film are larger than the corresponding dimensions of the bottom glass by 0.75mm to account for the size tolerance of the glass backer.)

Touch Window True-Flat Resistive Touch Screen film-film-glass construction - Film-Film-Film- PC Construction (5 layers)

Touch Window True-Flat Resistive Touch Screen film-film-film-pc construction

Feature

- Customizable 4-, 5- and 8-wire design and compatible with Multi-Finger resistive touch screen designs.

- Glass, Polycarbonate, and PMMA backer materials.

- Various thickness selections.

- Customizable tailing methods (indentation or cutout).

- Customizable plating service including drilling, rounded-corner grinding, etc.

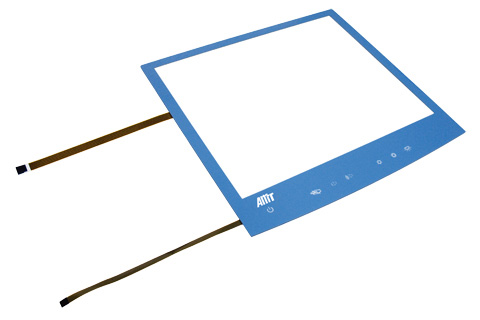

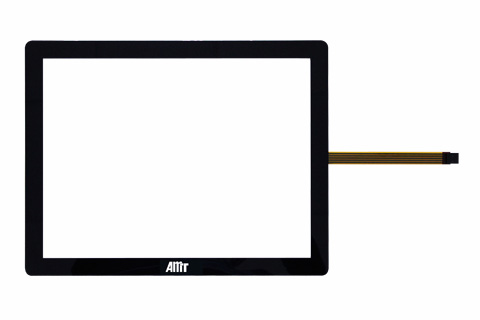

Framed Touch True-Flat Resistive Touch Screen

Framed Touch true-flat resistive touch screen is a simplified version of AMT's Touch Window resistive touch screen. Instead of an additional layer of décor film, a frame is printed directly to the underside of the upper ITO film of a Framed Touch true-flat resistive touch screen. This frame can be black or white and include customer logos. Framed Touch true-flat resistive touch screens utilize tail design typical to conventional resistive touch screens and require no additional design changes.

Features

- Very good light transmission rate.

- Straightforward construction.

- AG or clear surface treatment.

- 5-wire design.

- Glass backer.

- Various thicknesses available.

- Tail design similar to conventional resistive touch screens.

Specifications

| Optical | ● Light transmission: > 78% |

|---|---|

| Mechanical | ● Sizes: ◎ 5.7" to 24" diagonal size (Touch Window) ◎ 5.7" to 18.5" diagonal size (Framed Touch) ● ITO glass thickness: 0.7mm ~ 2.8mm ● Tail design: FPC type, Integral tail or others ● Tail terminator: ZIF, Berg, AMP, AMP compatible or others ● Input method: Finger, Gloved, Stylus ● Activation force: < 2.0N depending on design ● Surface hardness: 3H or higher |

| Environmental | ● Operating temperature: -20°C to +70°C ● Storage temperature: -40°C to +80°C ● Operating humidity: ◎ if temp. ≧ 40°C, humidity less than 80% RH ◎ if temp. < 40°C, humidity less than 90% RH ◎ No dew condensation ● Storage humidity: ambient humidity |

| Electrical | ● Insulation resistance: 10M ohm@25V DC ● Linearity: ◎ < 1.5% for 4-, 8-wire touch ◎ < 1.0% for 5-wire touch inner area ◎ < 1.5% for 5-wire touch perimeter area ● Contact bounce: ◎ < 10ms for 4-, 8-wire touch ◎ < 15ms for 5-wire touch ● Operating voltage: 5.5 V ● Contact current: 70mA (maximum) |

- Video

- Related Products

Resistive Touch Screen Control Board USB Interface

PenMount offers PM6300A control board with USB interface . The PM6300A supports 4, 8, and 5 wire...

DetailsResistive Touch Screen Control Board RS-232 Interface

PenMount resistive touch screen control boards communicate with the system via a RS-232 interface...

DetailsResistive Touch Screen Control Board RS-232 & USB Interface

The PenMount combination interface resistive touch screen control board has two types which...

Details

True-Flat Resistive Touch Screen Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of True-Flat Resistive Touch Screen. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.