Anti-ESD Coating Manufacturer in Taiwan - AMT

AMT introduces the Anti-ESD Coating Solution. We apply a layer of our exclusively developed Anti-ESD coating on the surface of the cover glass, enhancing the product's protection against ESD. The AMT Anti-ESD Coating can reduce static accumulation or accelerate static dissipation, improving the product's safety and stability. It is suitable for any product, especially those in dry environments prone to static generation or in machines with high-speed rotational friction. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

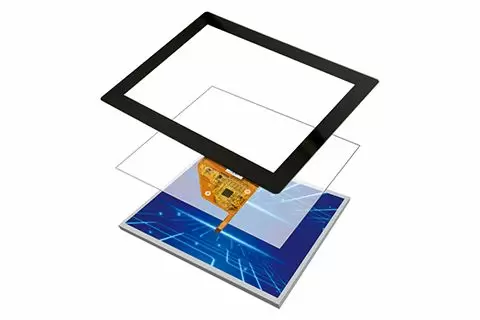

Anti-ESD Coating

Antistatic Coating

AMT introduces the Anti-ESD Coating Solution. We apply a layer of our exclusively developed Anti-ESD coating on the surface of the cover glass, enhancing the product's protection against ESD. The AMT Anti-ESD Coating can reduce static accumulation or accelerate static dissipation, improving the product's safety and stability. It is suitable for any product, especially those in dry environments prone to static generation or in machines with high-speed rotational friction.

In general, Electronic products require electrostatic discharge (ESD) protection. The voltage resistance of the IC electronic components used in these products is usually lower than ±2 kV, which makes these IC components susceptible to ESD from the environment or human contact. If the released voltage exceeds the component's tolerance, it can damage the electronic circuit, resulting in product failure or equipment malfunctioning.

AMT has developed anti-ESD coating that can be applied to glass. This coating makes the surface resistance of the cover glass within the range of 10⁷ to 10¹⁰ ohm/sq, which disperses or evenly distributes electrostatic charges. As a result, it gradually transfers and dissipates ESD to other conductive elements, such as air or moisture. This prevents direct ESD from entering electronic components and effectively enhances ESD protection. Additionally, the conductive glass's high resistance facilitates ESD's rapid dissipation into the surrounding air, reducing charge accumulation and extending the product's lifespan.

Features

- High resistance conductive material coating on glass

- It transfers and dissipates ESD to other conductive elements, such as air or moisture

- Surface Electric Resistance (Ω):10⁷~10¹⁰

- Electrostatic Discharge Protection: (according to IEC 61000-4-2, level 4/class B)

- Air Discharge: 30KV

- Contact Discharge: 30KV

Specification

- Transmittance(GFF):≥ 90%

- Surface Hardness:≥ 6H

- Viscosity: < 20 cps

- Density: 1 ± 0.5%

- ASTM G154 Cycle 1 - 500 hours

- MIL-STD 810H PRO 1 -500hours

Applications

- Electronic equipment rooms

- High-latitude regions

- Treadmill

- Car

Anti-ESD Coating Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Anti-ESD Coating. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.