Glass-Film-Glass Resistive Touch Screen Manufacturer in Taiwan - AMT

A Glass-Film-Glass (GFG) resistive touch screen is a resistive touch screen with an additional top layer of thin glass. Since the touch screen surface is glass and not film (standard resistive touch screen), surface of a GFG resistive touch screen is more resistant to scratches, high temperatures, and is easier to clean. A GFG resistive touch screen has a piece of glass with a thickness of 0.2mm laminated on top of a resistive touch screen. Glass with a clear surface finish will have a hardness of 5 Mohs. Certified resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards, ISO, UL E331240-A1-UL, REACH, and RoHS. All touch screen products are supplied with flexible production quantity and long term support.

Glass-Film-Glass Resistive Touch Screen

Scratch-resistant and chemical-resistant glass surface resistive touch screen

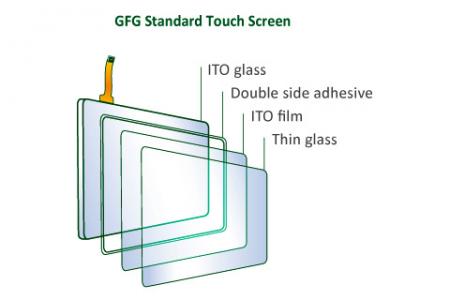

A Glass-Film-Glass (GFG) resistive touch screen is a resistive touch screen with an additional top layer of thin glass. Since the touch screen surface is glass and not film (standard resistive touch screen), surface of a GFG resistive touch screen is more resistant to scratches, high temperatures, and is easier to clean. A GFG resistive touch screen has a piece of glass with a thickness of 0.2mm laminated on top of a resistive touch screen. Glass with a clear surface finish will have a hardness of 5 Mohs.

Surface Coating

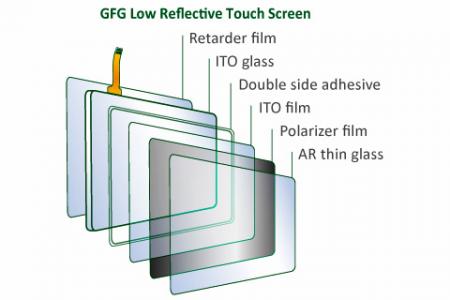

GFG resistive touch screen surface coatings include clear and Anti-Glare finishes. If the GFG resistive touch screen is installed on equipment used outdoors, a low-reflection coating can be added. GFG resistive touch screens are not only resistant to scratches and abrasion but also most chemicals, making GFG touch screens appropriate for specialized applications.

Glass-Film-Glass Resistive Touch Screen-POS

Features

- Sizes: 3" to 19" (0.2mm thin glass)

- Easy to cleaned surface.

- Corrosion and scratch resistance suitable for chemical-laden environments.

- Clear or Anti-glare surface finish.

- Average Activation Force: 0.5N ~ 1.5N

- Surface Hardness: Clear glass Mohs 5, AG glass 7H

- Light Transmission Rate: Over 80%

- Operating Temperature: -30 ~ 80°C

- Storage Temperature: -40 ~ 90°C

- Linearity: Under 1.5%

Specifications

| Optical | ● Surface Finish: Clear or Antiglare ● Light Transmission: > 80% |

|---|---|

| Mechanical | ● Sizes: 3" to 19" (0.2mm thin glass) ● ITO Glass Thickness: 0.7mm ~ 2.8mm ● Tail Design: FPC Type, Integral Tail or Others ● Tail Terminator: ZIF, Berg, AMP, AMP Compatible or Others ● Input Method: Finger, Gloved, Stylus ● Activation Force: ◎ 1.5N (maximum) for touch inner area ◎ 2.5N (maximum) for touch perimeter area ● Surface Hardness: ◎ For Clear Type Thin Glass: > Mohs 5 ◎ For AG Type Thin Glass: 7H |

| Environmental | ● Operating Temperature: -30°C to +80°C ● Storage Temperature: -40°C to +90°C ● Operating Humidity: ◎ If temp. ≧ 40°C, humidity less than 80% RH ◎ If temp. < 40°C, humidity less than 90% RH ◎ No Dew Condensation ● Storage Humidity: Ambient Humidity |

| Electrical | ● Insulation Resistance: 10M ohm@25V DC ● Linearity: ◎ < 1.5% for 4-, 8-wire touch ◎ < 1.0% for 5-wire touch inner area ◎ < 1.5% for 5-wire touch perimeter area ● Contact Bounce: ◎ < 10ms for 4-, 8-wire touch ◎ < 15ms for 5-wire touch ● Operating Voltage: 5.5 V ● Contact Current: 70mA (maximum) |

Applications

- Industrial Settings.

- Medical Devices.

- Food Preparation.

- Maritime, transportation, or aeronautical systems.

- Harsh environments such as gas stations or chemical plants.

- Video

- Related Products

Resistive Touch Screen Control Board USB Interface

PenMount offers PM6300A control board with USB interface . The PM6300A supports 4, 8, and 5 wire...

DetailsResistive Touch Screen Control Board RS-232 Interface

PenMount resistive touch screen control boards communicate with the system via a RS-232 interface...

DetailsResistive Touch Screen Control Board RS-232 & USB Interface

The PenMount combination interface resistive touch screen control board has two types which...

Details

Glass-Film-Glass Resistive Touch Screen Manufacturer - AMT

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Glass-Film-Glass Resistive Touch Screen. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Certified (ISO, UL, REACH, and RoHS) resistive, projected capacitive (PCAP) touch screens and PenMount touch screen controllers meeting international standards. All touch screen products are supplied with flexible production quantity and long term support.

AMT has been offering customers high-quality resistive and projected capacitive (PCAP) touch screens, and PenMount touch screen controllers, both with advanced technology and 20 years of experience, AMT ensures each customer's demands are met.

Mission & Vision

AMT is dedicated to quality. AMT's unique value lies in its ability to fulfill the diverse needs of customers.

Environmental & Energy Policy

AMT is committed to environmental conservation and the perpetuation of green energy.

Quality Certification

AMT has obtained ISO 9001: 2015, ISO 13485: 2016, ISO 14001: 2015, ISO 45001:2018, UL, REACH, and RoHS certifications.